THE ULTIMATE GUIDE TO HYDRAULIC EXCAVATOR PARTS SUPPLIER

In the ever-evolving world of construction and heavy machinery, hydraulic excavators play a vital role in transforming landscapes and completing projects efficiently. As any machinery operator or fleet manager will affirm, the quality and availability of hydraulic excavator parts significantly impact operational efficiency and project timelines.

UNDERSTANDING HYDRAULIC EXCAVATORS

Hydraulic excavators are powerful, versatile machines used for a range of tasks including digging, grading, and demolition. Their design heavily relies on hydraulic systems, which use fluid pressure to create the powerful motion needed for their operations. Understanding the anatomy and functioning of these machines is essential for anyone in the construction field.

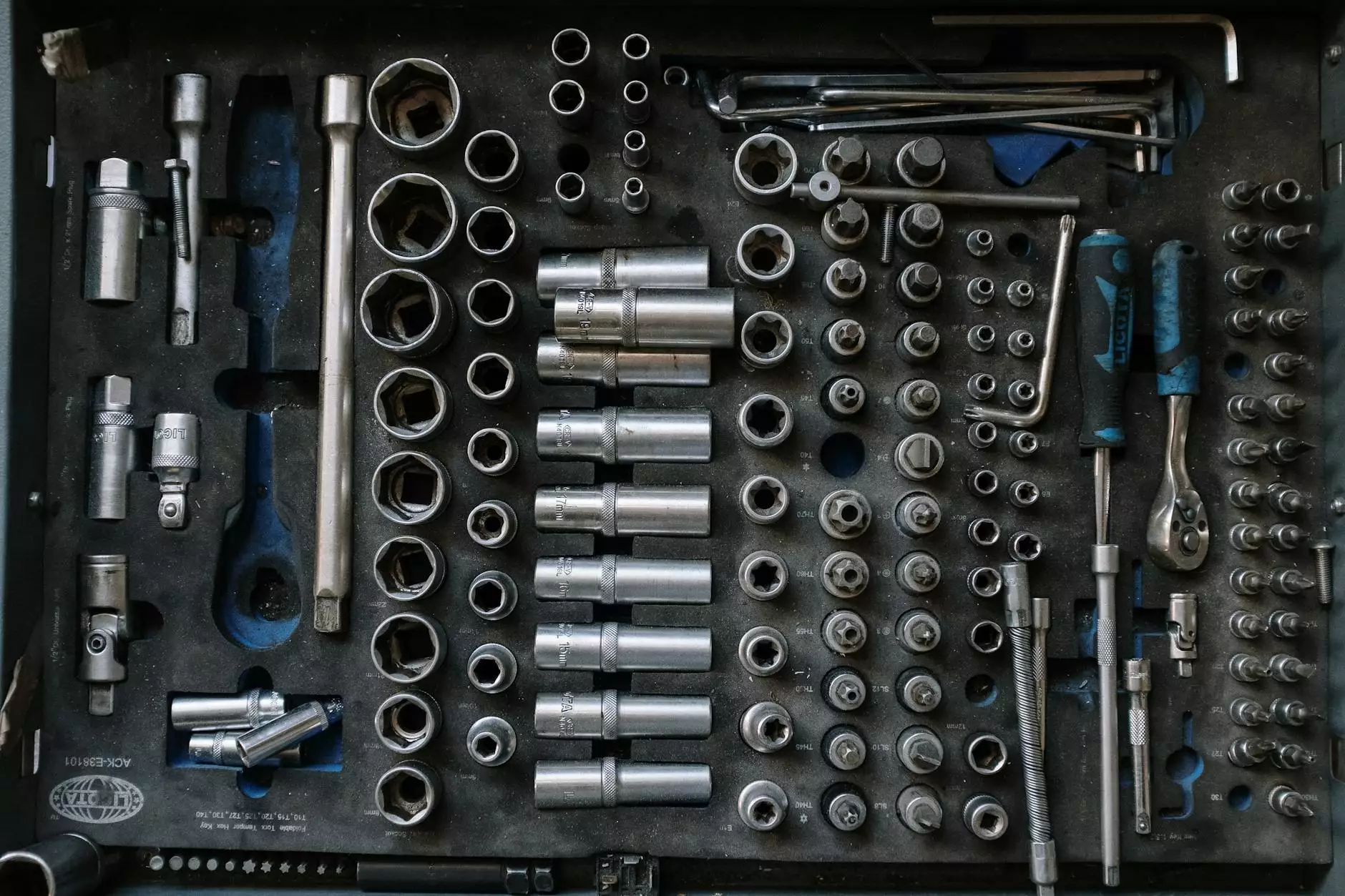

Key Components of Hydraulic Excavators

- Hydraulic Pumps: Converts mechanical energy into hydraulic energy to power the excavator.

- Hydraulic Cylinders: These are the actual moving components that control the boom, arm, and bucket.

- Tracks/Wheels: Provides mobility and stability on uneven terrains.

- Operator’s Cabin: A safe and comfortable workspace equipped with controls for operation.

- Attachments: Versatile tools like buckets, hammers, and grapples that increase functionality.

THE IMPORTANCE OF QUALITY PARTS

Every component of a hydraulic excavator works in unison to deliver its exceptional performance. Thus, maintaining these machines requires access to high-quality parts. Here are several reasons why choosing a reliable hydraulic excavator parts supplier is crucial:

- Safety: Quality parts ensure the safe operation of the machinery, reducing the risk of accidents.

- Efficiency: Reliable parts contribute to smoother operations, preventing downtime that can stall projects.

- Cost-Effectiveness: While cheaper parts might seem attractive, they can lead to frequent replacements, resulting in higher long-term costs.

- Longevity: Quality components enhance the lifespan of the excavator, providing better value over time.

WHAT TO LOOK FOR IN A HYDRAULIC EXCAVATOR PARTS SUPPLIER

With numerous hydraulic excavator parts suppliers in the market, it’s essential to select one that meets your specific needs. Here are critical factors to consider:

1. Experience and Reputation

Choose a supplier with a proven track record in the industry. Look for client testimonials and case studies to gauge their reputation and reliability.

2. Range of Parts Available

A comprehensive supplier will offer a wide range of components, including OEM and aftermarket parts. This range ensures that you can source everything you need from a single provider.

3. Quality Assurance

Verify if the supplier adheres to industry standards and quality certifications. This guarantee not only ensures the performance of the parts but also their reliability.

4. Customer Service

Responsive customer service is vital. You should feel comfortable reaching out for support, queries, or warranty claims.

5. Pricing and Payment Options

While cost shouldn’t be the only factor, it’s crucial to ensure that you’re getting a fair price for quality parts. Additionally, flexible payment options can make transactions smoother.

6. Shipping and Delivery

Look for suppliers who have robust logistics in place ensuring fast and reliable delivery to minimizes your downtime.

COMPARING OEM AND AFTERMARKET PARTS

When sourcing parts, you’ll typically come across two categories: OEM (Original Equipment Manufacturer) parts and aftermarket parts. Each has its pros and cons:

OEM Parts

OEM parts are made by the manufacturer of the equipment and are designed to meet specific standards of quality. Here are some advantages:

- Guaranteed Compatibility: Designed specifically for your excavator model.

- Higher Reliability: Rigorously tested, ensuring performance standard.

- Warranty Support: OEM parts typically come with robust warranty backing.

Aftermarket Parts

Aftermarket parts are produced by third-party manufacturers and can often be less expensive. Benefits include:

- Cost-Effectiveness: Generally cheaper than OEM parts, providing savings.

- Variety: Wider selection of products that may enhance functionality.

- Availability: Often easier to find than rare OEM components.

TIPS FOR MAINTAINING YOUR HYDRAULIC EXCAVATOR

Proper maintenance can significantly prolong the life of your excavator and minimize repair costs. Here’s how to maintain your machine effectively:

1. Regular Inspections

Perform routine inspections of all hydraulic components. Look for signs of wear or damage, and replace parts as necessary.

2. Keep Hydraulic Fluids Clean

Regularly check and replace hydraulic fluid to ensure the system runs smoothly. Contaminated fluid can lead to serious damage.

3. Monitor Performance

Pay attention to any unusual sounds, vibrations, or performance drops. Address potential issues before they escalate.

4. Regular Cleaning

Keeping the excavator clean prevents debris from entering the hydraulic system and damaging internal components.

5. Follow Manufacturer Guidelines

Refer to your manual for specific maintenance schedules and procedures laid out by the manufacturer.

SHOULD YOU CHOOSE LOCAL OR ONLINE SUPPLIERS?

In today’s digital age, sourcing parts can be done both through local supply houses and online platforms. Here are some considerations for both:

Local Suppliers

Pros:

- Ability to inspect parts before purchase.

- Immediate availability for urgent repairs.

- Personalized customer service.

Cons:

- Limited selection compared to online stores.

- Potentially higher prices due to overhead costs.

Online Suppliers

Pros:

- Wider selection of parts available.

- Competitive pricing to choose from.

- Convenience of ordering from anywhere.

Cons:

- Shipping times may delay repairs.

- Risk of incompatibility with specific machinery.

PARTNERSHIP WITH YOUR SUPPLIER

Establishing a strong partnership with your hydraulic excavator parts supplier is vital for the long-term success of your operations. Here are ways to strengthen that relationship:

1. Communication

Maintain open lines of communication for inquiries and feedback.

2. Consistency

Regularly purchase from the same supplier to build trust and familiarity.

3. Share Your Needs

Be upfront with your supplier about your project requirements and timelines to optimize support.

4. Loyalty Programs

Inquire if your supplier offers loyalty rewards for consistent business.

CONCLUSION

Navigating the world of hydraulic excavator parts suppliers requires understanding the machinery’s intricacies and the importance of quality components. By prioritizing quality, building solid relationships with suppliers, and taking meticulous care of your excavators, you ensure that your projects operate smoothly and efficiently.

For all your hydraulic excavator parts needs, consider visiting shophydraulicamerica.com, where you can find a vast selection of quality parts tailored to your specifications, ensuring your projects meet success without delays.